-

Posts

940 -

Joined

-

Last visited

Never -

Days Won

1

Content Type

Profiles

Forums

Events

Posts posted by Counterman

-

-

Transtar Industries announced the launch of its newest brand, Transmaxx, a line of customer-driven remanufactured transmission products.

Transtar partnered with ETE REMAN to launch three remanufactured-transmission electro-hydraulic control modules (TEHCMs) designed for General Motors six-speed-transmission applications.

Backed by a one-year unlimited warranty administered by ATSG, “each TEHCM is meticulously repurposed to ensure optimum performance and reliability,” according to Transtar.

“Our focus with Transmaxx is to bring to market-innovative remanufactured product solutions not currently available that solve customer repair shop needs,” said Neil Sethi, president and CEO of Transtar Holding Co. “Coupled with the backing of world-class organizations like ETE REMAN and ATSG and adding innovative technology solutions like Transtar RAP kit and Transend online ordering, we are very excited about evolving Transmaxx to become the go-to reman transmission brand for a broad array of product solutions.”

The product, along with the Transtar RAP kit for reprogramming, offers a complete repair solution for TEHCM needs, Transtar asserted.

“We’ve enjoyed a long and mutually beneficial partnership with Transtar. We can’t think of a better partner to launch our first TEHCM product offering,” said Noah Rickun, CEO of ETE REMAN. “Our commitment to quality sets us apart in the automotive aftermarket industry, and Transmaxx will offer the ultimate remanufactured product experience that only Transtar can provide.”

Transmaxx will be available exclusively at all Transtar, King-O-Matic and Transmart locations across North America and available online at Transend.

The post Transtar Launches New Brand of Remanned Transmission Products appeared first on Counterman Magazine.

-

AutoZone on Jan. 2 completed its previously announced leadership transition plan.

Phil Daniele became president and CEO. Daniele, a 30-year AutoZoner, previously served as executive vice president merchandising, marketing and supply chain.

Bill Rhodes, who most recently served as chairman, president and CEO, transitioned into the role of executive chairman. Rhodes served as AutoZone’s CEO for nearly 19 years.

“A very special congratulations to Phil on becoming AutoZone’s president and CEO,” Rhodes said in a news release. “For only the fifth time in our company’s rich history, we have a new CEO. I am tremendously excited about AutoZone’s future and continued growth under Phil’s leadership.”

AutoZone first announced the leadership changes on June 26.

“I am extremely honored and enthusiastic about the opportunity to serve as president and CEO of AutoZone, a company that I love dearly and have been a part of for over three decades,” Daniele said. “Our ability to put the customer first is and will forever be the key to our accelerated growth and continued success. Both Bill and I deeply believe that AutoZone’s best days lie ahead.”

The post Phil Daniele Takes Over as AutoZone CEO appeared first on Counterman Magazine.

-

Lucas Oil Products, a long-time partner of both Richard Childress Racing and ECR Engines, will expand its partnership with Richard Childress Racing and Kyle Busch in 2024, the companies announced.

The Indianapolis-based company will partner with RCR and Busch for multiple NASCAR Cup Series races and also continue as the official motor oil of ECR engines.

Lucas Oil will also serve as primary sponsor for both Kyle and Brexton Busch. Kyle will feature the Lucas Oil colors when he competes in the Micro Sprint car series. Kyle will debut the Lucas Oil colors on December 26 in The Tulsa Shootout. Brexton will also have Lucas on board in his 2024 racing program.

“RCR and ECR share our passion for motorsports, from the grassroots to the highest levels of the sport,” said Brandon Bernstein, director of partnership marketing for Lucas Oil Products. “We share Kyle’s passion for short track racing and are excited to help Brexton take the next step in his career. We’ve seen first-hand the benefits of our partnership, especially as it relates to technology transfer over to short track racers and everyday consumers. We’re proud to continue to commit our resources in R&D and production, and to highlight our premier oil performance with sponsorship of the No. 8 Chevrolet,” Bernstein added.

Lucas Oil has served as the official lubricant of RCR and ECR Engines since 2014 and is the official motor oil of ECR Engines. RCR, ECR and Lucas Oil have gone to NASCAR Victory Lane together more than 20 times since the partnership began.

Busch piloted the No. 8 Lucas Oil Chevrolet to victory in the 2023 NASCAR Cup Series race at Auto Club Speedway in Fontana, Calif. The win came in their first race together and was the first victory for Lucas Oil in the NASCAR Cup Series. It was also the first for Busch at RCR and extended his streak of 19 consecutive seasons with at least one victory at NASCAR’s highest level.

“RCR and ECR have benefited greatly from having a lubricants partner with strong roots in racing,” said Torrey Galida, president of RCR. “It was incredibly gratifying to see the No. 8 Lucas Oil Chevrolet in Victory Lane. It was a testament to all of the resources, expertise, and hard work the Lucas/ECR team has committed to giving us a huge competitive advantage,” Galida concluded.

The post Lucas Oil Expands Racing Partnerships in 2024 appeared first on Counterman Magazine.

-

After a successful partnership in 2023, Dayco announced that Tony Stewart Racing (TSR) has signed on to use its blower belts again during the 2024 NHRA Mission Foods Drag Racing Series.

Both Matt Hagan, four-time Funny Car champion, and Tony Stewart, NASCAR, INDYCAR and USAC Champion, will compete in their respective categories using Dayco blower belts on the track.

After finishing third in 2022, Hagan came back with a vengeance in 2023, placing first and earning the World Championship title. He has a total of 49 career event titles, with six of those victories from last season.

Stewart will be making his NHRA Top Fuel debut in 2024, after finishing second in the NHRA Lucas Oil Drag Racing Series national championship standings in 2023 and finishing second in the North Central Region.

Both Hagan’s Funny Car and Stewart’s Top Fuel dragster are driven at speeds in excess of 330 mph down the track, and Dayco blower belts not only held up all season in intense conditions but enabled both cars to perform at optimal levels, according to Dayco.

“I’m looking forward to continuing our partnership with Dayco in 2024,” Stewart said. “Getting behind the wheel this season, I know their belts will help Matt Hagan and I perform at the highest level on-track.”

The Dayco 11-millimeter blower belt is engineered specifically for use by Top Fuel and Funny Cars with nitromethane engines. It features a hybrid carbon cord encapsulated in custom rubber compounds and patented low-friction PTFE tooth fabric, according to Dayco. It has a standard 11-millimeter pitch, is 84 millimeters wide and has 145 teeth.

“It feels great knowing our Dayco blower belts helped ensure the drivers’ were behind the wheel of machines set up to win during the 2023 season,” said Jay Buckley, director of marketing and training, Dayco North America. “We can’t wait to see what next season has in store for the TSR team and look forward to our belts helping them bring home more wins.”

Hagan and Stewart will kick-off the 2024 NHRA season March 8-10 at the NHRA Gatornationals in Gainesville, Florida.

The post Dayco, Tony Stewart Continue Partnership for 2024 Racing Season appeared first on Counterman Magazine.

-

Prior to the mainstream production of front-wheel-drive vehicles and independent rear suspension, the drivetrain on practically every vehicle consisted of a transmission, driveshaft and solid rear axle assembly.

Things were simple. Driveshafts had universal joints (U-joints) at each end and if nothing else, most people were familiar with U-joints and had to replace them at one point or another.

The driveshaft was nothing more than a round tube that transferred the power output from the transmission to the differential. At each end was a U-joint that allowed the angle of the driveshaft to change as the suspension moved up and down over bumps, or the drivetrain angles changed under acceleration.

Today, “driveshaft” is another one of a long list of automotive terms often used and confused with other components.

So where did the confusion begin? In simpler days, the rear driveshaft was all there was. Then, four-wheel-drive vehicles began to utilize a short driveshaft that went from the transfer case to the front differential. But it still was a driveshaft.

As independent rear suspension made its way to American automotive design, early systems utilized an even shorter version of a driveshaft to transfer power from the rear differential to each wheel. As opposed to running longitudinally, or front to back, these driveshafts ran latitudinally, or side to side, and since two of them were required for the rear axle assembly, they also got a new name: halfshafts.

Independent rear suspension was already popular on many rear-engine European vehicles, utilizing halfshafts with constant-velocity (CV) joints. As front-wheel drive (FWD) became popular, CV-joint-equipped halfshafts were utilized due to the greater range of motion and smoother operation they offered over U-joints.

Equipped with CV joints, halfshafts utilized on a FWD vehicle became widely known as “CV shafts.” However, terminology differs between people and geographical location. Some refer to CV shafts as “driveshafts,” and the typical longitudinal rear driveshaft is known to many as a “propeller shaft.” Still yet, some call CV shafts “halfshafts,” which now are the most common type of lateral shaft on the rear of all-wheel-drive or rear-wheel-drive independent-suspension vehicles as well as FWD.

Today, CV joints also are utilized in place of U-joints on many longitudinal drive shafts, both for rear-wheel and all-wheel-drive applications. The bottom line is you may have to ask a few questions to make sure you’re talking about the same part as your customer. But that bowl of spaghetti aside, let’s look at some of the basics of the tried-and-true original longitudinal-type driveshaft.

Fancy? No. Important? Yes.

A driveshaft begins as nothing more than a round tube, either steel or aluminum. The tube is cut to the proper dimensions, then the ends are pressed into the tube. The ends may be a yoke, slip yoke, slip shaft or even a CV-joint hub on newer vehicles. There are multiple options depending on the drivetrain and application.

The ends are then welded on, and the shaft is checked and straightened if necessary. U-joints, CV joints or bearings are installed, and the entire assembly is balanced. An important detail to share with your customer is some driveshafts are two- or three-piece shafts (primarily on trucks or vans), and these are balanced and keyed so when installed, care must be taken to install them properly to maintain the balance.

Typically, a driveshaft may last the life of a vehicle, and replacing the joints – especially U-joints – is a common repair. Any time a driveshaft is removed from the vehicle, it should be marked so it can be reinstalled in the same position, which can help prevent any driveline vibrations. When replacing U-joints, it’s important to make sure the caps of the U-joint fit tightly in the yoke. If they fit loose in the ear of the yoke, the yoke is worn or damaged and the driveshaft will need to be replaced.

So, a driveshaft is nothing fancy. It’s a tube with ends. But as mundane as they may seem, it’s an important component, and even more so where high-performance is concerned.

Often overlooked, the combination of too much power and too high of a rotational speed can cause a driveshaft to twist and bend, and ultimately fail. Performance driveshafts differ based on the quality and diameter of the tubing, and the manner in which they are balanced. Aluminum is a common material because of weight savings and the reduction of rotational mass, but it’s ultimately not as strong as steel.

Have you heard of a driveshaft loop? In the event a U-joint breaks, it’s a safety device that keeps the driveshaft from hitting the road and pole-vaulting the car (really) or keeps it from coming through the floorboards. They’re important for any high-horsepower street or race car, where the chance of breaking a U-joint is much higher.

Don’t Forget About Torque Tubes

Think you have driveshafts down? Well, I skipped one. There’s another type you may have heard of called a torque tube. A torque tube almost looks like a traditional driveshaft setup at a glance, but with a closer look, all you can see is that the tube is bolted directly to the transmission and rear differential. Inside is a smaller-diameter solid driveshaft.

Torque tubes were the prevalent type of driveshaft used in early American auto production, and they have their pros and cons depending on the type of vehicle and the suspension. There are many different designs, again depending on vehicle and suspension type. By the early 1960s, the majority of torque-tube drivetrains were replaced by the traditional driveshaft setup. Even so, torque tubes continued to be utilized on various models from economy to high-end sports cars, and they’re still in use today where the benefits play into vehicle design.

The post Driveshaft Dynamics appeared first on Counterman Magazine.

-

DMA Industries recently announced that Philip Champion is the new DC manager for its Tabor City, North Carolina, distribution centers.

Champion brings over two decades of expertise in warehousing and distribution operations management, quality control and health and safety to DMA, according to the company. Notably, he was pivotal in launching a startup for Newell Brands in Gastonia, North Carolina, in 2021.

His extensive background includes a long tenure with Mann+Hummel since 2001. At Newell Brands, he excelled as the outbound operations manager, strategically guiding a new distribution-center startup and overseeing returns/rebox DC operations, along with quality and HSE work teams.

“Philip’s wealth of experience and leadership is an invaluable asset, providing essential support to our DC operations team as we navigate our new strategic direction,” said Misty Funderburk, DMA’s VP of operations.

The post DMA Names Philip Champion Manager for North Carolina DCs appeared first on Counterman Magazine.

-

Akebono Brake Corp. recently expanded its line of ProACT and EURO ultra-premium disc brake pads by five new part numbers: ACT2230, ACT2231, ACT2372, ACT2383 and EUR2136.

Premium stainless-steel abutment hardware is included in the kits that require it.

The recent ProACT release adds coverage for the 2020-2017 Acura MDX; 2023-2021 Ford F-150, 2023-2022 Expedition, 2023-2020 Explorer and 2023-2020 Police Interceptor Utility; 2022-2018 Honda Odyssey; and 2023-2020 Lincoln Aviator and 2023-2021 Navigator.

The EURO release adds coverage for the 2023-2019 Volvo XC40.

“We are thrilled to announce this release of five new ProACT and EURO part numbers that add late-model coverage for Acura, Ford, Honda, Lincoln and Volvo, significantly expanding coverage for more than 3 million VIO (vehicles in operation),” said Kirby Pruitt, product development manager at Akebono Brake Corp. “This reflects our commitment to innovation and meeting the needs of our customers. All of these parts are in- stock and ready for shipment.”

A complete listing of Akebono applications for these parts and the rest of Akebono Brake’s product offering is available in the web catalog at akebonobrakes.com or directly via https://akebonobrakes.mypartfinder.com/.

The post Akebono Expands Line of ProACT, EURO Disc Brake Pads appeared first on Counterman Magazine.

-

NPW has acquired the New Jersey Auto Parts location in Miami, marking a strategic expansion for the company.

New Jersey Auto Parts, a family-owned business with roots dating back to 1979, has been a familiar presence in the Miami market for decades.

The Tamiami store, part of the New Jersey Auto Parts portfolio since 2008, will transition to the Johnny’s Auto Parts brand, marking the debut of the first Johnny’s store in South Miami.

“I’ve had a tremendous relationship with NPW and the Pacey family for decades,” said former owner Roger Tapanes, a key figure in the legacy of New Jersey Auto Parts. “The decision to sell the business to NPW made perfect sense. I am confident that my loyal employees will be well taken care of, and under NPW’s guidance, the business is poised to reach new heights.”

The deal closed Dec. 21.

“We are excited to announce the acquisition of the New Jersey Auto Parts Tamiami location and the introduction of Johnny’s to the South Miami community,” said Chris Pacey, CEO at NPW. “This strategic move aligns with NPW’s vision to expand our footprint while maintaining the exceptional service and product quality our customers expect. The trusted relationship we’ve built with the previous owners has laid a solid foundation for this transition.”

NPW, a shareholder of the Aftermarket Auto Parts Alliance, will continue to fly the Auto Value flag in conjunction with Johnny’s branding.

The post NPW Acquires New Jersey Auto Parts Tamiami Location in Miami appeared first on Counterman Magazine.

-

You might not be able to see it, but an accessory-drive belt is always both speeding up and slowing down. When a piston accelerates downward after the ignition of the fuel and air, the crankshaft speeds up and then slows down as it reaches the bottom of the stroke. These changes in speed are minimal, but big enough to cause problems over time.

If the pulses aren’t minimized, they can hammer the belt and the attached rotating components. On a four-cylinder engine, the degrees of rotation between power pulses are greater than on a V-8 – so the amount of change in speed on the four-cylinder pulley is greater than on a V-6 or V-8. This has a direct effect on how the belt system is designed.

The belt-drive system is working hardest when the engine is at idle. When the engine is below 1,000 rpm, the alternator, A/C compressor and power-steering pump are putting the greatest strain on the belt.

Some of the forces can be taken up by the belt slipping on the pulleys. But, slipping causes friction and wear on the belt, as well as flutter. Over time, the slipping can get worse as removal of material from the ribs causes the belt to bottom out.

There are three components that help to keep the belt on the pulleys without slipping. The tensioner, harmonic balancer and decoupler pulley work together to keep the accessory-belt system quiet and the belt lasting until the replacement interval.

Tensioner

The tensioner applies force on the belt. Some tensioners have devices that dampen the movement of the spring and arm, helping to keep constant force on the belt even under a wide variety of conditions.

Harmonic Balancer

The harmonic dampener puts a layer of soft material between the crankshaft and outer ring of the pulley. The material helps to dissipate the power pulses and resonant frequencies. While the dampener may only flex one or two degrees of movement, this takes a lot of strain off attached components.

Decoupler Pulley

Some alternators have a decoupler pulley. This device serves two purposes. First, it helps to decouple the pulley from the alternator with a one-way clutch. The decoupler reduces parasitic losses by not having to fight against the momentum of the armature in the alternator while the engine is decelerating and accelerating.

Some decoupler pulleys have a spring and friction dampener to reduce vibration. When an alternator decoupler pulley is compromised, it can no longer absorb the same level of abuse, which has a trickle-down effect throughout the system.

Alternator decouplers and pulleys should be inspected every 10,000 miles for wear. Early design versions have a service life of 40,000 to 60,000 miles, with more recent versions lasting more than 100,000 miles.

When inspecting a decoupler or pulley, there are two signs that replacement is needed. First, after shutting down the engine, if there’s an audible buzzing, the bearings in the pulley have likely failed. The second sign depends on whether the vehicle has a one-way clutch (OWC), overrunning alternator pulley (OAP) or decoupler (OAD).

With the inspection cap/cover removed and the center locked, turn the pulley or decoupler with the appropriate tool. If it’s an OAP or OWC, the pulley can only be turned in the clockwise direction. If it’s an OAD, a counterclockwise turn will reveal a noticeable increase in spring force; a clockwise turn will only have slight resistance. The tensioner, harmonic balancer and decoupler pulley work together to keep the belt in contact with grooves in the pulleys. The three components are engineered together to match the engine. If one part is compromised, all are compromised, including the belt.

The post Serpentine Belts Have a Strong Supporting Cast appeared first on Counterman Magazine.

-

NRS Brakes has added premium galvanized brake-pad kits for 2022-2024 Ram ProMaster covering 1.2 million vehicles, including ambulances.

The brake kits also include abutment hardware and caliper-piston cushions.

“Canadian-made Premium Galvanized Brake Pads by NRS Brakes feature technology that you can see,” the company said in a news release. “Galvanized steel incorporates PACE-award-winning, patented NRS mechanical fusion technology. The result is the world’s quietest, safest and longest-lasting brake pads. Galvanized steel that outlasts the friction, ensuring it won’t fail as a result of corrosion-material delamination from the backing plate, giving you a license to feel safe.”

NRS Brakes feature no glue, no paint and no toxins, NRS noted.

All galvanized brake pads use OE-specified technology, according to the company.

PART # AXLE POSITION APPLICATIONS NS2467 REAR Ram ProMaster 1500 (2022-2024);

ProMaster 2500 (2022-2024);

ProMaster 3500 (2022-2024)The post NRS Adds Galvanized Brake-Pad Kits for 2022-2024 Ram ProMaster appeared first on Counterman Magazine.

-

In the almost 100 years of the Genuine Parts Company (GPC), parent company NAPA and Motion, it has had five CEOs. You can literally count them on one hand. With that brings “an incredibly consistent, powerful and longstanding culture” of being a solutions-oriented business for customers, said Will Stengel, president and COO of GPC. But, when COVID-19 hit, GPC was forced to rethink its usual strategies for getting the right part to the right customer at the right time. As a result, it underwent a technological revolution.

“I think it’s fair to say any company that’s had success over decades needs to continuously challenge itself to improve,” Stengel told attendees at the MEMA Aftermarket Technology Conference in October. “What COVID did for GPC is prove that we could improve our business model, which we’ve done.”

It started with hiring the right people. In 2021, GPC hired Naveen Krishna as its EVP and CIDO — the first technologist to run GPC’s IT department. Then, Susan Starnes, a former Lowe’s executive, became the company’s first vice president of emerging markets to help create innovative strategies for our business. The next step was to take GPC’s solutions-oriented approach to solving customer problems and apply technology to it.

“All the fundamental elements of our business have a dedicated technology strategy behind it,” Stengel explained during the conference, held at GPC’s headquarters in Atlanta. “That lines up with this whole idea that tech is at the core of what we do and what we want to do.”

GPC is one example of an aftermarket company that is no longer thinking of itself as strictly in the automotive and industrial space. Instead, its focus has shifted to become a technology company in the automotive aftermarket. If you ask Paul McCarthy, president and CEO of MEMA Aftermarket Suppliers, he thinks all companies should adopt that mindset.

“Technology is driving our success, efficiency and our future. This is the reality for the aftermarket,” he said. “I’m issuing a call to action: a demand for innovation in our industry from suppliers.”

Amid the discussion around technology trends, a common theme that surrounded innovation and efficiency was what we’re calling the buzzword of 2023: artificial intelligence. Like many industries, the automotive aftermarket is delving into AI and ways it can help businesses be more productive and effective as future mobility continues to inch closer to needing aftermarket solutions.

AI Applications in the Aftermarket

Picture this: You know when and where a repair is going to happen and can get the part that technician needs to the shop before the vehicle comes in for service. That is just one example of how AI can make our industry more efficient. But what exactly is AI?

Tilak Kasturi, founder and CEO of Predii, a company that develops automotive-specific AI applications, said AI is the simulation of human intelligence processes by machines on certain business intelligence (BI), such as data, content, reports, etc. It utilizes machine learning, neural networks and natural language processing to do things such as recognize patterns, make decisions and judge like a human.

“BI is aggregated data and analytics, such as market intelligence, sales forecasting, etc.,” he explained. “If you say ‘right time, right part, right place,’ that is BI, but ‘right part, right place, ahead of time’ is AI. Knowing beforehand requires some prediction ability.”

David Brondstetter, a 40-year aftermarket veteran and CEO of SureCritic, an AI software that responds to customer reviews for repair shops, added that AI is applying algorithms to a data set to understand what is going to happen in the future. A good example is parts ordering.

“If you’re able to predict that, let’s say an O2 sensor is nearing end of life, you can predictably set an appointment for that customer at the shop, get the part ordered, and then have the customer come in,” he said. “The problem with parts ordering right now is you rely on all these things to happen, and then you assume your customer’s going to

come in.”Scott Brown, industry ambassador and co-founder of the Diagnostic Network, a digital resource and forum for technicians, said an example of how his company has used AI is in the form of AiDN, an AI-powered assistant. Brown said AiDN will detect a vehicle-specific discussion in a Diagnostic Network forum and will respond like a member of Scott’s team.

“If you think about the deliverable and who it’s being delivered to, it can take an apprentice technician or middle-educated technician and get him started on the right pathway,” Brown said. “We will mature this technology and continue to train it on expert information. We think it will streamline [a technician’s] process of getting to a successful result faster in the future.”

A Long Road Ahead

While companies like Predii, SureCritic, Diagnostic Network and others are implementing AI for various solutions, industry experts say more work needs to be done. For example, access to good industry data, and education around the types of AI to use are critical. Data security and protecting your IP is another issue.

Kaivan Karimi, global partner of strategy and cybersecurity at Microsoft, presented the concept of “responsible AI” at the Technology Conference as a guideline for businesses when experimenting with this technology.

“There is the wild, wild West AI and then there is responsible, curated AI,” he said, adding that responsible AI is setting standards and guardrails around how you’ll use the tool while making sure your data is secure. “AI is a great productivity, tool, but people need to expect a set of standards when using it.”

Knowing the correct AI tools to use comes down to working companies that specialize in industry data. For example, ChatGPT is not meant for industry specific data, said Predii’s Kasturi.” It can actually take you to the wrong path,” he said.

When speaking about data and predicting when a part will fail, Right to Repair is at the heart of the aftermarket’s data access troubles. Vehicle telematics data is crucial for building out technology to predict when parts need replaced and the right way for a technician to fix a vehicle.

“We know what the world looks like when there is real repair access,” McCarthy said. “Take the Phillips Connect trailer. Just with your brakes, it can tell you their performance, wear and exactly how much life is left in key components so that you can do the repair before something breaks. But this concept and this positive future is only possible with Right to Repair.”

Cybersecurity is another big issue playing a part in using AI. Microsoft’s Karimi said securing your company’s data in each step can decrease data breaches and cybersecurity attacks.

“You need to protect the factories, the lines, the cars, the enterprise, the network, the backends, the cloud, and then some security operation center at a center that ties the whole thing together,” he said. “Your strengths are only as good as the weakest link.”

McCarthy added that if a Right to Repair law is passed, and safe, open connectivity is achieved, it can expand technology and services and improve forecasting and inventory for all involved along the supply chain. GPC’s Stengel added that for aftermarket companies, any technology—such as AI—must prove to make the industry companies more profitable, in addition to efficient.

“We talk about data, we talk about digital, we talk about the role in which technology serves and improves the customer experience, but, ultimately, it’s got to drive a financial expression for the business, which is growth and operating profitability,” Stengel said.

Industry Jobs of the Future

With an exciting future in technology ahead, aftermarket companies may be forced to rethink roles at their companies. The question on many minds is “Will AI take my job?” The answer might surprise you, Karimi said.

“When I give talks to engineers, and they ask, ‘Am I going to lose my engineering job?’ I say, You may lose your engineering job to another engineer who knows AI. You have to adopt AI as a tool. It’s a massive productivity gain. It’s around to stay.”

As the use of data and AI applications increase, SureCritic’s Brondstetter thinks that data scientists are going to become more prominent in aftermarket organizations.

“Before this rise of generative AI, most of the data scientists were working on normalizing data,” he said. “Now that we’re in a state where we’ve got computing power to handle all this data, these predictive algorithms can normalize the data and data scientists can work on tweaking the model. That’s where you get a real generative AI. I think that position will become more prominent because the core of AI is having data scientists who understand that.”

Predii’s Kasturi said in his experience, automotive data analysts and experienced technicians are critical to ensuring AI’s future in the aftermarket. Skilled technicians, for example, can verify the results of generative AI models.

“I see that as the future where technicians are hands-on, ratchet-and-wrench-type people, but also are powering some of these expert-based systems,” Kasturi said. “They know their data really well. They know their codes, they know their parts, they know the fix.”

Brown agreed, adding that an aging or injured technician can now turn into a triage specialist that takes the AI and vehicle information, and then prepares a repair path plan and assigns it to the other technicians in the shop. “This new generation can hopefully rebirth our service industry,” he added.

The post Artificial Intelligence in the Automotive Aftermarket appeared first on Counterman Magazine.

-

Automotive lore calls them idiot lights. For years, critical engine functions were monitored by gauges. Oil pressure, engine-coolant temperature and generator/alternator operation were displayed for easy viewing by the driver.

Why the auto manufacturers initially decided to switch over to warning lights is anybody’s guess, but the motoring public in general was quick to express their disdain over it. Since these lights quickly earned the reputation for being useless – or not conveying warning over a bad situation until damage had already been done – they just as quickly earned their less-than-endearing nickname.

In the mid-1930s, Hudson was the first automobile manufacturer to use warning lights instead of gauges, and it wasn’t long before others followed suit. They quickly became standard, with performance vehicles being the exception with optional gauge packages.

Today, warning lights are still the standard, but it’s a completely different playing field. Oil pressure, coolant temperature and charging-system operation are still the three most important factors, and gauges for these systems have seen a resurgence in popularity, especially in trucks. However, the simplicity of only having those three systems to monitor is long gone.

Today, if it was theoretically possible to have an informative gauge for each and every system on a car, dashboards would look like the cockpit of an airplane. Possible or not, it isn’t realistic, and on top of that, computer technology has made warning-light function accurate and dependable – a far cry from the “idiot” lights of old. In most cases, warning lights today will notify you of a “condition” long before it becomes a problem, and even if it’s one of the three big factors, they’re accurate enough to give you plenty of time to get off the road and shut down to avoid a catastrophic failure.

The hard part is with the number of different warning lights today, it’s hard to know what they all mean, especially with continuously changing technology. And have you seen the size of owner’s manuals? Looking up any one item can send you on a wild goose chase bouncing around through multiple pages to maybe and only maybe find what you’re looking for.

In addition to the growing number of different symbols and warnings, there also are many colors in addition to red. Most manufacturers have incorporated the green-yellow-red idea since we’re used to what that means in relation to traffic signals: green, go; yellow, caution; red, stop. But don’t be surprised to see blue and white thrown in.

Luckily, the symbols for most warning indicators are standardized across all makes and models, making them easily recognizable. But there are still a lot of them. If there’s a light on, there’s a good possibility your customer will ask about it. Here’s a list to help you sort through them.

Check Engine/MIL/Service Engine Soon

This is the main one. The malfunction indicator lamp (MIL) has seen a few different variations over the years, including simple versions with the text “Check Engine” or “Service Engine Soon,” and the now widely recognized engine symbol with a lightning bolt in the middle.

An illuminated MIL means the engine control unit (ECU) recognizes there is a problem with one of the monitored engine systems, which can affect emissions, drivability or dependability. When the light is on, one or more trouble code(s) will be stored by the ECU.

A scan tool is required to access and read these trouble codes, which allow a technician to follow a specified path for diagnosis. An illuminated MIL won’t go out until the problem has been corrected or the trouble code has been erased. However, depending on the problem, if the code is erased without performing any repairs, the code may reset immediately, which will in turn cause the light to immediately come back on. In some cases, the light may take a day or two to come back on.

If the problem is corrected and the code isn’t erased (for example, your customer makes the repair but doesn’t have a scan tool), the code will be erased by the ECU and the light will go out. But, this may take as long as a week, depending on the driving habits of the vehicle owner.

If the MIL is blinking, it means there’s a problem that may damage the catalyst, and the vehicle should be immediately taken in for service. This is generally the result of a cylinder misfire, and a blinking MIL is almost always accompanied by a noticeable symptom of the engine or vehicle shaking.

Another interesting aspect of the MIL is its key-on/engine-off function. When you turn the key on with the engine off, the MIL should illuminate. On some vehicles it may shut off after a few seconds. This is normal. If the light begins to blink, this is an indicator that the readiness monitors aren’t complete, and the vehicle isn’t ready for an E-Check. Of course, readiness monitors are a subject all on their own, but this can be useful to know for anyone in an E-Check area.

Odometer-Triggered Warnings

As emissions regulations were tightening prior to the advanced computer controls we’re used to today, some manufacturers began to use odometer-triggered warning lights for emissions-related systems as early as the mid-1970s. Many of these were oxygen-sensor or EGR (exhaust-gas recirculation) warning lamps, designed to come on at a specified interval for service or replacement of specific parts.

These are rarely seen today, and OBD II, which became mandatory on all cars in the United States in 1996, hastened the end of these types of warnings. If you happen to see one, keep in mind on older vehicles that there’s no scan tool to reset them. There’s a specific procedure that differs per manufacturer, and it’s often a mechanical reset, sometimes on the back of the odometer itself or in a “trick” location.

Battery Light

Here’s an easy one. An illuminated battery means there’s low system voltage for some reason. Is it the battery, the alternator, wiring or a broken belt? Bottom line: When this light comes on, you better get where you’re going quickly – especially at night – or you’re going to run out of power.

Cooling System

The thermometer in water is widely recognized as a cooling-system warning, but it can mean many different things. Red means trouble no matter what, but it can mean that the coolant level is too low, or the engine temperature is too high. These also can flash, indicating there’s another malfunction within the cooling system. On some vehicles, this light also may be green or blue when the vehicle is cold, letting you know to let the engine warm up before any hard acceleration.

Brake-System Lights

The common symbol for brake systems is a circle with an arc on each side. While I’ve never had any documented proof, I picture it as the circle indicating a brake drum or rotor, and the arc on each side indicating the brake linings that act upon them. There are multiple different variations of the symbol.

Red is bad. An exclamation point in the middle means the fluid level is low or the system has lost brake pressure. A ”P” in the middle means the parking brake is engaged.

There also are multiple yellow variations of the light. The letters “ABS” in the middle means there’s a malfunction with the antilock braking system. When the arcs on the side are dashed, this indicates the brake-pad linings are worn very low. This usually is a feature only on higher-end vehicles. If there’s a crossed-out bulb in the middle, it means there’s a brake light out, or a problem with the brake-light circuit.

A green indicator with a foot in the middle means you must step on the brake before you can shift the vehicle out of park or start the car if it’s a push-button start. Most brake warning lights occupy their own spot on the instrument cluster, with the exception of the fluid-level/brake-pressure warnings, which generally utilize the same lamp.

Oil Pressure/Oil Level

The oil can is another one of the three big ones. Red means low oil pressure, and other than when the ignition itself is on, this light should go out when the engine is running. Low oil-level warnings are sometimes indicated by this light in yellow, or sometimes by a separate warning.

Tire Pressure

Easily as well-known as today’s “Check Engine” light is a low-tire warning light, part of the tire-pressure monitoring system (TPMS). It means you have a tire low on air, but if the light flashes initially, it means there’s a problem in the system – usually that one of the sensors isn’t communicating with the system – and it should be diagnosed by a professional technician.

Seatbelt/SRS/Airbag

These are symbols that everyone knows. The seatbelt warning symbol was one of the first to appear in cars in addition to oil, temperature and charging. The airbag symbol means there’s a problem with the supplemental restraint system (SRS). But these days, the SRS is a lot more than just the airbag in the steering wheel. It could be the passenger airbag, side or curtain airbags, seat belt pre-tensioners or more. There’s a lot to these systems and they shouldn’t be taken lightly. Your safety – and potentially your life – may depend on the operation of this system.

Transmission Warnings

The transmission warning light is shaped like a gear and can have an exclamation point inside or a thermometer inside. Red with a thermometer indicates a transmission overheating problem and yellow usually a shifting or gear-ratio problem.

Service Required

Many vehicles utilize lights or warnings to indicate that a regular service is due, from an oil change to a tune-up, or even inspection services. These vary widely between manufacturer, and are often simple text messages, or in some cases just the image of a wrench.

ABS/Traction-Control Systems

Even though we already covered ABS warning lights, it’s common for these to come on in conjunction with traction-control system (TCS) warning lights since the two systems generally share data from wheel-speed sensors. If there’s a problem with one system, there’s likely a problem with the other, or an ABS problem often causes the TCS to shut off, again due to the sensors. Many vehicles have the option of turning off the TCS, in which case the light illuminates by itself with the word “OFF.”

Diesel

Diesel engines have a few additional warning indicators that differ from gasoline engines. The glow-plug light, which looks like a couple loops of wire, illuminates either when the system is operating, or if there’s a malfunction. In most cases, if there’s a malfunction, there also will be a trouble code and the standard MIL will be illuminated.

Newer diesels have warning lights to indicate when the diesel-exhaust particulate filter (DPF) needs service, and when the diesel-exhaust fluid (DEF) is low. These lights vary widely in appearance, and some of them look downright silly like a third-grade art project. But when you look closely, you’ll see they’re trying to depict particles, fluid and the movement of exhaust.

Unless the car is new to them, diesel owners will be well-aware of the DEF light since the vehicle won’t run when it’s out of fluid.

Washer Fluid Low

This is an easy one: The view you have with the wipers on, fluid and a fountain.

Exterior-Light Warnings

There are many different exterior-light warnings. The most common is the age-old blue “high-beam” indication, but some vehicles feature this warning in green to let you know the low-beam headlights are on, or they just have the letters “DRL.” A bulb-out warning is the image of a bulb; the bulb inside the universal sign for brakes indicates a brake lightbulb out.

Many new cars have adaptive headlights, meaning they self-adjust to compensate for vehicle loads and steering. A red warning with arrows indicates a malfunction with this system.

Door/Trunk/Hood Ajar

This one is always red. Most today depict the exact location of the offender. Some are just text.

Low Fuel

We all know what this means. Sometimes it’s just a round light that comes on as the gauge nears “E.”

Drivetrain Warnings

There are probably more variations of these symbols than any other. “O/D” stands for overdrive and indicates the overdrive is turned off or disabled for some reason. If there’s a malfunction in a system that causes the overdrive to be disabled, there will most likely be an illuminated MIL to accompany it.

All-wheel-drive (AWD) and four-wheel-drive (4WD) systems that can be controlled by the driver often have text indications of what’s engaged and what gear range, or the universal symbol indicating front and rear differentials and a center transfer case is commonly used as well.

Full-time AWD systems just utilize the lamp when a problem prevents proper system operation, and depending on the type of system and the inputs it receives, there may be other warning lights on at the same time such as the MIL or

ABS indicators.ADAS

Advanced driver-assistance systems (ADAS) came along with their share of indicators to warn us of lane departure, distance warnings, forward collision avoidance and blind-spot monitoring.

And More!

It can seem like a never-ending list. “EPC,” common on some European cars, stands for electronic power control and means there’s a problem with the throttle system. A key indicates a problem with the vehicle anti-theft system, and depending on whether it’s steady or flashing, it can clue you in to the problem.

A steering wheel with an exclamation point means there’s a problem with the power steering. A snowflake means the temperature is close to or below freezing and there could be ice on the road. The cruise-control symbol is a small speedometer with an arrow pointing to a specific spot, sometimes white or yellow to indicate the cruise control is on and green to indicate it’s set.

The bottom line? You still may need to go on that wild goose chase in the owner’s manual to determine the exact meaning of any given indicator. And what about electric vehicles, you might ask? Yes, they have them. That’s for another day.

The post Interpreting Dashboard Warning Lights appeared first on Counterman Magazine.

-

Brake master cylinders convert the force exerted on the brake pedal into hydraulic force that is transmitted to the individual brake hydraulic cylinders located at each wheel. Their basic operation is easy to understand, but before getting into that, let’s look at how impressive the brake system actually is.

Have you ever tried to stop a car that rolls unexpectedly down an incline, even an incredibly slight one? It’s not easy. As a matter of fact, most of the time, you just get out of the way and hope it doesn’t hit anything before it stops. Cars are heavy. We’re not strong enough to stop them, even with all our might.

So how is it we’re able to stop them with one foot and the brake pedal? It’s not because we’re that strong. It’s because of hydraulics, the basis for brake-system operation. The theory of hydraulics states that the pressure exerted anywhere on an enclosed liquid is transmitted equally in all directions.

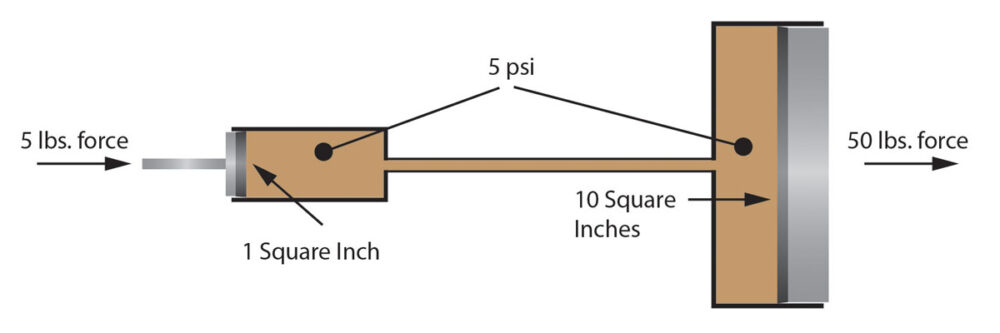

A visual representation can make it easier to understand. Figure 1 shows a cylinder with a piston that has a surface area of 1 square inch. Five pounds of force are being exerted on the end of the piston, which creates 5 pounds per square inch (psi) of pressure inside the system. Since liquid doesn’t compress, that pressure is transmitted equally to all interior surfaces of the cylinder.

That same 5 psi travels through the line into the larger cylinder that has a piston with a surface area of 10 square inches. Since the pressure is transmitted equally to all surfaces, 5 psi is being applied to each square inch of the larger piston, and multiplying the pressure by the area gives the output of the larger piston. This is what allows master cylinders to be relatively small, yet a brake system to be so powerful.

How Do They Work?

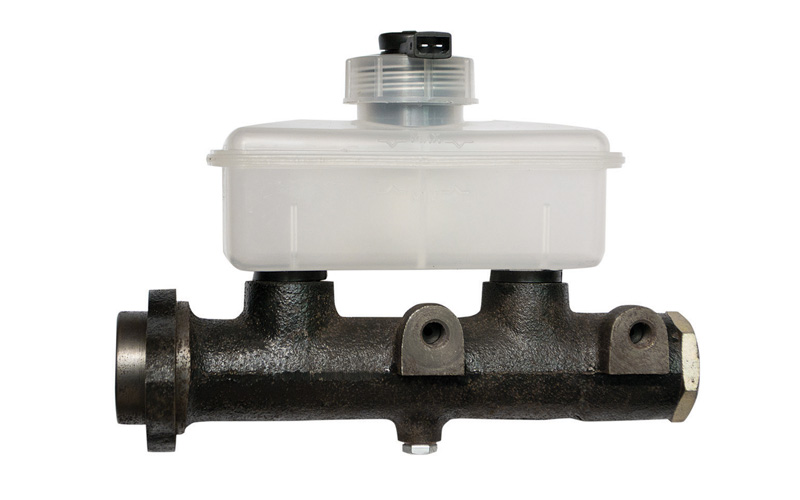

The primary parts of any master cylinder are the reservoir, the body and the piston(s). The reservoir can be made of cast iron, aluminum or plastic; the bodies will be cast iron or aluminum. Cast-iron or aluminum reservoirs are usually cast together with the body of the master cylinder, making them appear as one single piece. This is the original type of master cylinder on most “classic” cars.

When plastic reservoirs are used, they typically sit directly on top of the master cylinder, but they also can be mounted remotely if there’s no room, with a hose leading to the master cylinder.

The piston is located in a bore within the body of the master cylinder, and when the brake pedal is depressed, the force on the piston pressurizes the brake fluid and pushes it through the lines. A series of valves and ports further controls the flow and return of the fluid inside the master cylinder.

For many years, master cylinders were of the single-piston type, meaning only one piston pushed the fluid to all four wheels. The problem with this design was if there was a pressure loss anywhere in the system, there was a complete loss of brakes.

By the late 1960s, dual-piston master cylinders were mandatory on all new cars. A dual-piston master cylinder has two separate braking circuits, which can be split diagonally or front to rear, but either way, the important factor is you can still stop the car with a pressure loss on one circuit.

Whether it’s a diagonal or front-to-rear split depends on the vehicle. For example, a front-to-rear split is acceptable on vehicles with an even front-to-rear weight division, but when most of the vehicle weight is in front – such as on a front-wheel-drive vehicle – the system is split diagonally, since the rear brakes alone wouldn’t be enough to stop the vehicle.

Maintenance

One school of thought says there’s no actual maintenance on the master cylinder, and this is loosely correct. However, regularly flushing the brake fluid is routine maintenance that not only maintains proper braking, but also will extend the life of all brake components, including the master cylinder. Due to the corrosive nature of brake fluid – which gets worse the older it gets and the greater amount of moisture it absorbs – the seals, valves, piston and bore inside a master cylinder are easily damaged by dirty fluid.

Signs of Trouble

There are some telltale signs of a failing master cylinder. The first one is a slow fluid loss with no outwardly visible leak. The only possible location for an external leak is at the rear of the bore, where the pistons slide in during assembly. It’s often hard to see a leak, since the fluid leaks out the back into the brake booster or inside the vehicle when the master cylinder is mounted to the firewall. If there is regular fluid loss but no external leaks can be seen, look closely at this area.

Brake fluid damages paint, and a close inspection usually shows softened paint around the mounting ears of the master cylinder, indicating a leak. In some cases, you may have to unbolt the master cylinder to inspect it for leaks. Occasionally, the seals between the reservoir and master cylinder can leak as well, but these are usually available separately.

If the brake pedal slowly sinks to the floor when you’re pressing on it, this indicates fluid is leaking internally past the piston seals and the master cylinder must be replaced. Eventually, this will lead to complete failure of the master cylinder, resulting in a pedal that goes completely to the floor and no brakes.

If a brake system experiences a sudden loss of braking force and the pedal goes to the floor, this generally indicates a broken brake line or hose, which also will be evident by rapid loss of fluid. Master cylinders themselves rarely exhibit sudden failure. They almost always give warning in the way of slow leaks or slow leak-down of the brake pedal, which means it’s time to replace.

Replacement

When your customer is installing a new master cylinder, they’ll need brake fluid first and foremost, and they may ultimately need a lot more when they go to bleed the system if they find bleeder screws that won’t open.

However, the most important advice you can give them is to bench-bleed the master cylinder following the instructions and using the bleeding hardware that comes with it. You can assure them it’s a simple and quick process, but a potential nightmare if they don’t. This is also one of the most important times to use a fender cover. Even the slightest drop of brake fluid on the paint will begin to etch into it immediately, and it’s a quick and easy way to avoid it.

The post Stopping Power: Brake Master Cylinders appeared first on Counterman Magazine.

-

1

1

-

-

Photo caption: From left, Claudia and Dr. David Fry (standing) are pictured as Dr. Fry receives the Wings of Freedom Award in 2022 in Bay Harbor, Michigan.

Northwood University announced the passing of former President David E. Fry, “a visionary leader, esteemed educator and beloved patriarch in the Northwood University family.”

Fry, who served as Northwood’s CEO from 1982 to 2006, passed away Tuesday, Dec. 19.

“Dr. Fry fostered Northwood University’s growth and progress as the longest-serving president and left an indelible mark on the institution,” reflected Northwood President Kent MacDonald. “Today, Northwood continues to advance the mission personified by Dr. Fry to develop free-enterprise leaders across America and around the world.”

Fry began his distinguished career as an economics professor with research and teaching interests in business, global economics and free markets. As president, he focused on creating an environment where this passion could be passed on to generations of students through the University’s philosophy, which values individual freedom and responsibility, earned success, moral law and the importance of free enterprise.

Fry proudly exemplified these institutional tenets of “The Northwood Idea,” the university said.

“Dr. Fry’s legacy includes leading Northwood through significant change, including growing the University academically from an institute to a university and opening the DeVos Graduate School of Management in 1993,” stated Kristin Stehouwer, provost, and vice president, academic affairs. “The more than 23,000 students who proudly graduated from Northwood University while Dr. Fry was leading from the helm – alumni who have gone on to impact private industry – is a testament to his leadership.”

The Early Days

At age 22, David Fry was part of an extraordinary faculty class recruited to Northwood in 1965. He became an intellectual descendant of Dr. V. Orval Watts, Northwood’s first legendary faculty member who gave shape and form to The Northwood Idea. Beloved in the classroom, Fry was named “Outstanding Teacher of the Year” by students in 1967 and 1968.

Fry was so talented that the school’s founders – Arthur and Johann Turner and Gary and Willa Stauffer – promoted him to an administrator role in 1969. In 1971, the founders gave him a mission to plant seeds of enterprise in Indiana, where he flourished. As much as he enjoyed teaching, he had an inherent gift to lead, inspire optimism, and influence different constituencies to share a common dream.

Along the way, he had taken time to establish solid academic credentials. Just as the school’s fortunes started to sour in the mid-1970s, Fry had fortuitously taken a sabbatical to earn his doctorate in business administration.

In a historic move, the Northwood Board of Trustees appointed Fry president and CEO of the Northwood Institute in 1982, making him one of the youngest college presidents in the United States.

Nancy Barker, a Midland resident who has served multiple roles with Northwood since 1971, including vice president of university relations, reflected on how he started as a young professor and eventually became one of Northwood’s greatest leaders.

“David evolved over the years. He was respected and had a wonderful relationship with the professors because he had been a faculty member and fully understood their important role in the classroom and for the success of Northwood,” Barker said. “David was a dynamic and challenging leader. He expected and encouraged those around him to do their best and gave them the support and opportunity to do that. His officers were a team who worked pretty much 24/7, as did he. David took the original Turner-Stauffer vision to a whole new level; his impact was international and yet still very personal.”

“All our lives were devoted to Northwood, this small growing institution, and Dr. Fry was our leader who paved the way.”

As involved as Johann Turner and Willa Stauffer were in their respective husbands’ work, so was Fry’s wife, Claudia. She is known as half the team that transformed Northwood from the early 1980s until Fry retired as its president in 2006.

“Claudia was always there for David,” reminisced Dr. Timothy Nash, Northwood vice president emeritus and director of the McNair Center for Free Enterprise. “She was the Rock of Gibraltar, the anchor in his life who played the more direct role in raising their two wonderful children, Daniel and Julie. Claudia has always had a strong intellect, passion, and interest in The Northwood Idea, global economics and business.”

“David has had a much better and more fulfilled life with Claudia by his side, and Northwood has a larger global footprint because of the two,” Nash added.

Expanding Academic Offerings

Under Fry’s leadership, Northwood experienced major academic expansions, including seeing Arthur Turner’s dream of a Florida campus come to fruition in West Palm Beach in 1983. He also fostered professional development partnerships with businesses and industry, the military, and community colleges.

Northwood began recruiting underserved students who needed access to various delivery methods and options to complete their degrees. Now known as Northwood Online, this was the start of Northwood’s Adult Degree Program, a delivery of content that enhanced access to higher education for adult learners who couldn’t attend college due to time constraints.

The DeVos Graduate School of Management was born in 1993 under Fry’s leadership. Since its beginning, the graduate school has attracted students worldwide. More importantly, its graduates have become entrepreneurs, leaders in the industry, mentors, and role models.

A University Well-Led, A Life Well-Lived

After facing many transitional and financial challenges, Fry and his team elevated Northwood to new heights. Campuses expanded, programs improved and grew and university status was achieved. Once back on solid footing, leaders focused on creative opportunities and innovations that lay ahead, distinguishing the Fry legacy.

“David’s great contribution was leadership,” stated Dr. Robert Serum, a long-time academic leader and innovator of international programs at Northwood, who is credited with navigating significant educational innovations for over two decades, starting in the late 1980s. “There are a lot of good managers out there, but there aren’t a lot of good leaders. David could walk into a room full of CEOs, all of whom had big egos, and before you knew it, they all wanted him as a friend. He was very popular wherever he went with faculty and staff, with other administrators and teachers, and especially with businesspeople. He epitomized what they believed in, free enterprise and every dimension of The Northwood Idea.”

Those who worked with Fry noted he had a brilliant mind and was a spell-binding speaker.

“His eloquence was so outstanding,” stated Dr. Marjorie Hohman, former board of trustee member, Distinguished Women honoree, and honorary doctoral degree recipient. “He was a people person, first. He was very good at connecting with people and holding their attention because he was such an eloquent speaker. He could stand in front of a crowd and captivate them because his command of the English language was superb.”

Hohman admired Dr. Fry’s influence on those he worked with. “The most outstanding thing about him was his leadership abilities and how he was able to get the best out of people,” she said. “He was such a mentor to so many.”

In honor of the tremendous progress made under Fry’s watch, the Northwood community came together to fund the David E. Fry Endowed Professorship to celebrate his retirement.

Recognizing his outstanding contributions to Northwood, in 2009, the University vested upon Fry its highest honor, Doctor of Laws, Honoris Causa.

Most recently, in 2022, Fry received the Wings of Freedom Award, created in honor of Northwood University’s own Dr. Dale Haywood. Northwood bestows this honor upon individuals whose lives have contributed to human progress, individual liberty, and economic and social prosperity.

“Dr. Fry’s legacy lives on at Northwood University, and we are forever thankful for his transformative role in our history,” stated President MacDonald. He continued, “Over my career, I have had the opportunity to research academic leaders around the globe and it is clear to me that Dr. Fry was one of the most transformational leaders in American higher education.”

Donors who would like to support Fry’s legacy can do so through a donation to the David E. Fry Endowed Professorship. Donations can be made online or by calling Northwood University Advancement at 989-837-4356.

The post Northwood U Celebrates Life of Former President David Fry appeared first on Counterman Magazine.

-

MAHLE Aftermarket announces the remaining two winners of the inaugural “Powered by MAHLE” Engine Giveaway.

The winner of a 302 Ford small-block engine is based in Killingworth, Connecticut, and can look to take home an engine backed with 315 horsepower and built by the technicians at Jasper Engines & Transmissions.

The Gen III HEMI 7.0L engine built by Moonshine Speed Shop is going to one lucky winner in Curran, Michigan.

“Congratulations to the winners of these premium engine parts,” said Jon Douglas, president, MAHLE Aftermarket North America. “It was awesome to be able to partner with some of our Team MAHLE members to pull together such a memorable program filled with some incredible prizes. As our inaugural ‘Powered by MAHLE’ engine giveaway comes to a close, we are very pleased with the response we have gotten from our customers and fans and want to also express our gratitude to everyone who enter our sweepstakes and made it such a success.”

In addition to the engine, all four winners of this year’s sweepstakes program received a one-night hotel stay and entry to the Performance Racing Industry (PRI) show in Indianapolis, which took place Dec. 7-9 at the Indiana Convention Center.

Winners who attended this year’s PRI show also were invited to a special “meet-and-greet” with a few “Team MAHLE” partners – the likes of which included members of Kalitta Motorsports, John Force Racing, Tony Stewart Racing and others.

The post MAHLE Selects Remaining Winners of 2023 Engine Giveaway appeared first on Counterman Magazine.

-

NPW announced “the resounding success” of its 33rd Annual Charity Golf Tournament.

The tournament took place Dec. 10 at the esteemed Miami Lakes Golf Club, formerly Don Shula’s Golf Club.

The event brought together more than 100 channel partners, customers and industry leaders for a day of golf and goodwill, all in support of First Tee of Miami – a nonprofit organization dedicated to empowering youth through the game of golf.

The tournament, featuring a scramble format, catered to golfers of all skill levels, and offered various prizes for accomplishments such as the longest drive, closest to the pin and outstanding team performance.

“Our Annual Charity Golf Tournament has been a cherished tradition for over three decades, and this year’s gathering exceeded our expectations,” said Chris Pacey, CEO at NPW. “It was heartening to see so many people from the industry come together to make a positive impact on our community.

“Teaming up with First Tee of Miami adds an extra layer of significance to the event. First Tee is doing great work in the community, and we are proud to contribute to their mission.”

NPW extended its gratitude to all participants, sponsors and contributors who made this event a success, and said it looks forward to continuing its philanthropic initiatives in the years to come.

The post NPW Holds Annual Charity Golf Tournament appeared first on Counterman Magazine.

-

Parts Authority recently named FCS Automotive as its 2023 Supplier of the Year.

The announcement was made during the recent 2023 Vendor Reception and Award Ceremony in Las Vegas.

The criteria for the Parts Authority Supplier of the Year award include contributing to consistent performance; providing best-in-class market coverage and high-quality products reliably; excellent fill rates; timely cataloging support; and maintaining high levels of customer satisfaction.

FCS Executive VP June Zhou and Sales Manager Jerry Miller were on hand to accept the award on behalf of FCS’s entire team.

“FCS Automotive remains committed to supporting The Parts Authority with industry-leading coverage, high-quality products, exceptional service levels and ongoing support to help drive business growth for many years to come,” FCS said in a news release.

The post Parts Authority Honors FCS as 2023 Supplier of the Year appeared first on Counterman Magazine.

-

Shop-Ware, a San Francisco-based provider of automotive repair shop management software, announces its first direct telephone integration with partner Amazing 7 LLC.

“Telecommunications integration across hardware and backend software represent Shop-Ware’s latest expansion of shop management solutions to uniquely solve shops’ needs to inspire consumer confidence across all aspects of the repair experience,” Shop-Ware said in a news release.

The product launch offers staff members valuable context to incoming phone calls, to respond to customers personally and intelligently, according to the company.

Simultaneous, on-screen notifications give staff members pertinent information to incoming calls, including current repair status, returning customer inquiries and lifetime value, as well as unidentified numbers for new customers or solicitations. Staff can quickly link to relevant repair orders or customer lookups based on phone-number match criteria, Shop-Ware noted.

“Shop-Ware’s vision is to reduce administrative work and inspire consumer confidence; this launch addresses both,” said Carolyn Coquillette, CEO of Shop-Ware. “Amazing 7 takes our shops to the next level, to empower their staff every time the phone rings: to convert a stressful interruption to a delightful opportunity, and ultimately differentiate their business.”

When an incoming phone call rings the shop’s phones, designated Shop-Ware users receive an in-app notification about the phone call, including customer name and lifetime value (when applicable), most recent visit, repair-order status and a link to the repair order. Cases for multiple customer matches or unidentified numbers are also handled. Quick links allow staff to answer the phone informed on the caller context to personalize their response accordingly.

“Amazing 7 is excited to partner with Shop-Ware to bring this intuitive addition to their best-in-class shop management system,” says Aimee Morley, owner of Amazing 7 LLC. “Imagine when the phone rings and the customer record is presented in front of your service advisor with the knowledge of the customer being a first time, second time or long-term customer. This is going to make the service advisors look like superstars to the customer.”

The A7 integration is available to all Shop-Ware customers. To take advantage of it, subscribers also must be enrolled with A7. For more information, click here.

The post Shop-Ware Announces Partnership with Amazing 7 LLC appeared first on Counterman Magazine.

-

The National Institute for Automotive Service Excellence (ASE) has announced its award winners for 2023.

“Each year, ASE takes great pleasure in recognizing those individuals who have distinguished themselves in the automotive service industry. Together with our industry partners and award sponsors, we salute the best of the best,” said Tim Zilke, ASE president and CEO. “The honored individuals come from all segments of the automobile, collision, truck, school bus, parts, educator and training sectors. Although they come from different areas, they all share a commitment to excellence.”

Award Winners

Auto Value/Bumper to Bumper/ASE Master Automobile Technician of the Year

- Harrison Keyes, Jerry’s Automotive Service LLC (Waukesha, Wisconsin)

Axalta/ASE Collision Repair & Refinish Technician of the Year

- James Rice, Ford Body Shop (Carthage, Missouri)

Big O Tires/ASE Master Automobile Technician of the Year

- Brandon Stoutmeyer, MFA Petroleum (Lebanon, Missouri)

BMW/ASE Master Automobile Technicians of the Year

- Patrick Nicodemus, BMW of Des Moines (Clive, Iowa)

- James Troxell, Apple BMW (York, Pennsylvania)

- Christopher Wilder, BMW of San Diego (Spring Valley, California)

- Timo Wolf, Momentum BMW (Houston, Texas)

BMW/ASE Master Collision Repair & Refinish Technician of the Year

- Gabriel Qahtani, Platinumwerks Collision (Cocoa, Florida)

BodyShop Business/ASE Master Collision Repair & Refinish Technician of the Year

- Thomas Baunach, PA Brown Daub Chevrolet (Bethlehem, Pennsylvania)

Bridgestone Retail Operations/ASE Master Automobile Technician of the Year

- Andrew Richards, Firestone Complete Auto Care (Grand Prairie, Texas)

Byrl Shoemaker/ASE Education Foundation Instructor of the Year

- Scott Fisler, Milwaukee Area Technical College (St. Francis, Wisconsin)

CCAR/Electude/ASE Instructor of the Year

- Tracey Hicks, Frederick County Public Schools (Frederick, Maryland)

Cloyes/ASE Automobile Technician of the Year

- David Senula, Gloucester County (Franklinville, New Jersey)

Delco Remy/ASE M/H Truck Electrical/Electronic Systems Technician of the Year

- David Harrach, City of Mesa Fleet Department (Gold Canyon, Arizona)

Discount Tire/ASE Automobile Technician of the Year

- Joe Bologna, Ellisville Tire and Service (St. Louis, Missouri)

Enterprise Holdings/ASE Master Automobile Technician of the Year

- Joseph Lanham, Enterprise Holdings (Mount Washington, Kentucky)

First Student/ASE Master School Bus Technician of the Year

- Joseph Taylor, First Student (Glenside, Pennsylvania)

Freightliner/ASE Master M/H Truck Technician of the Year

- Jason Spore, Peach State Truck Centers (McDonough, Georgia)

Garage Gurus/ASE Automobile Master + A9 + L1-L4 Technician of the Year

- Jesse Keyes, Dobbs Tire & Auto (St. Peters, Missouri)

Gates Tools for Schools/ASE Instructor of the Year

- Joseph Young, Miramar College (San Diego, California)

Gates/ASE Master Automobile + L1 Technician of the Year

- Jason Rigby, Christian Brothers Automotive (Cumming, Georgia)

GM/ASE Service Consultant of the Year

- David Hudson, Caldwell County Chevrolet (College Station, Texas)

GM/ASE Master Automobile Technician of the Year

- Woodrow Robison, Lee Chevrolet/Buick (Greenville, North Carolina)

GM/ASE Parts Specialist of the Year

- Jeff Armour, Feldman Chevrolet (Mason, Michigan)

Honda/ASE Master Automobile Technician of the Year

- Frank Currid, Proctor Honda (Crawfordville, Florida)

Acura/ASE Master Automobile Technician of the Year

- John Heberlein, Courtesy Acura (Morrison, Colorado)

I-CAR Platinum/ASE Master Collision Repair & Refinish Technician of the Year

- Barto (Tim) Gruber, Classic Bodyworks (Pearl City, Hawaii)

Midas International/ASE Master Automotive Technician of the Year

- David Lang, Midas/Auto Resource Center (Huntington, Virginia)

Mitchell1/ASE Technician of the Future

- Benjamin Fisher, Advance Development and MFG (Branford, Connecticut)

Motor Age Training/ASE Master Automobile + L1 Technician of the Year

- Jared Deskins, Nissan North America (Hammond, Louisiana)

NAPA/ASE Master Automobile Technician of the Year

- Steve Vinkemeier, Pro Auto Inc. (Plato, Minnesota)

Navistar/ASE Master M/H Truck Technician of the Year

- James Singleton, Highway Motors Inc. (Bridgewater, Virginia)

Navistar/ASE Master School Bus Technician of the Year

- Jeremy Adkins, Sternberg Automotive Group (Ferdinand, Indiana)

Nissan/ASE Master Automobile Technician of the Year

- Shawn Bauman, Mark Arbuckle Nissan (Shelocta, Pennsylvania)

Infiniti/ASE Master Automobile Technician of the Year

- Barry Nielsen, Ray Catena Infiniti of Bridgewater (South Amboy, New Jersey)

Pep Boys/ASE Master Automobile Technician of the Year

- Jeremy Luther, Pep Boys (Marrero, Louisiana)

Pronto Auto Service/ASE Master Automobile Technician of the Year

- Ian Sharp, Schweitzer’s Automotive (Junction City, Oregon)

Parts Plus Car Care Center/ASE Master Automobile Technician of the Year

- Colin Gallagher, Shaffer Auto (Port St. Lucie, Florida)

Snap-on/ASE Master Automobile Technician of the Year

- Dylan Dickey, Honest Accurate Auto Service (Colorado Springs, Colorado)

NEXIQ/Snap-On/ASE Master M/H Truck Technician of the Year

- Craig Bekkala, Bekkala’s Diesel Repair, LLC (Calumet, Michigan)

Car-O-Liner/ASE Master Collision Repair & Refinish Technician of the Year

- Joseph Dukeman, Caliber Collision (Smithfield, North Carolina)

Stellantis/ASE Master Automobile Technician of the Year

- Zachary Bollinger, Cole Chrysler Dodge (Arroyo Grande, California)

Subaru University/ASE Technician of the Future

- Pierce Cartwright, CMA’s Subaru of Winchester (Slanesville, West Virginia)

Subaru/ASE Master Automobile Technician of the Year

- James Pedicone, Chilson Subaru (Eau Claire, Wisconsin)

TechNet Professional/ASE Master Automobile Technician of the Year

- Chad Van Handel, Van Handel Automotive (Sisters, Oregon)

TechNet Professional/ASE Service Consultant of the Year

- David Anderson, Reggie’s Motorworks (Noblesville, Indiana)

Toyota/ASE Master Automobile Technician of the Year

- Harold Williams, Toyota of North Austin (Belton, Texas)

Lexus/ASE Master Automobile Technician of the Year

- Timothy Putt, Bobby Rahal Lexus (Enola, Pennsylvania)

Toyota/ASE Master Collision Repair and Refinish Technician of the Year

- William Lehmann, Freeman Collision Center (Santa Rosa, California)

Lexus/ASE Master Collision Repair and Refinish Technician of the Year

- Jared Luttrell, Sewell Lexus of Fort Worth (Burleson, Texas)

TravelCenters of America/ASE Master M/H Truck Technician of the Year

- Lucas Coyle, Travel Centers of America (Upland, Indiana)

USAF/GM/ASE Master Automobile Technician of the Year

- SSgt Fernando Carrasquillo Morales, United States Air Force (Crestview, Florida)

ZF Aftermarket/ASE Master Automobile Technician of the Year

- Roger Briggs, H-Tel Autocare (Jonesborough, Tennessee)

The post ASE Announces 2023 Award Winners appeared first on Counterman Magazine.

-

Transtar Holding Co. announced the acquisition of Arch Auto Parts, which has 21 locations throughout New York City and the surrounding areas.

Arch will become part of NexaMotion Group (NMG), “a family of innovative and industry-leading automotive aftermarket businesses,” Transtar said in a news release.

Schwartz Advisors represented Arch Auto Parts in the transaction. The terms were not disclosed.

“Arch Auto Parts aligns perfectly with our strategic goals and marks the largest acquisition for Transtar Holding Company in general automotive repair parts distribution, which exemplifies our commitment to growth in this segment,” Transtar Holding Co. President and CEO Neil Sethi said. “I am incredibly proud to welcome Arch under the NexaMotion Group umbrella. We are excited to partner with the entire Arch team and look forward to accelerating our growth plans.”

Following the acquisition, Arch Auto Parts and its team members will operate as a business unit of NexaMotion Group.

Arch Auto Parts owner and CEO Chris Bodh will join the executive leadership team as group president of general repair businesses. Through this combination, Arch will be positioned to rapidly accelerate the growth of its expansive products, services and locations.

“This is a great opportunity for Arch to join NexaMotion Group,” said Bodh. “Having their support and partnership gives us a major advantage to do more for our team members, customers and suppliers, and we’re excited to be part of a great company that shares our values and culture.”

The post Transtar Holding Co. Acquires Arch Auto Parts appeared first on Counterman Magazine.

-

Democrats in Congress are warning that the National Highway Traffic Safety Administration’s (NHTSA) proposed guidance for implementation of Massachusetts’ Data Access Law conflicts with the Biden administration’s pledged support for Right to Repair, the CAR Coalition reported.

As reported by POLITICO, former auto repair shop owner and REPAIR and SMART Act co-sponsor Rep. Marie Gluesenkamp Pérez (D-WA) joined Reps. Jake Auchincloss (D-MA) and Jared Golden (D-ME) in sending a letter to Secretary of Transportation Pete Buttigieg and NHTSA Administrator Sophie Shulman outlining concerns that NHTSA’s latest guidance may unfairly harm independent repairers.

Citing differences in remote-data access, the lawmakers’ letter warns that NHTSA’s current guidance creates a “double standard” between automaker repair networks and independent repair businesses that may “entrench manufacturers’ dominance in the repair market in the long run … [and] harm competition.”