-

Posts

19 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Everything posted by Mengjuan Zhu

-

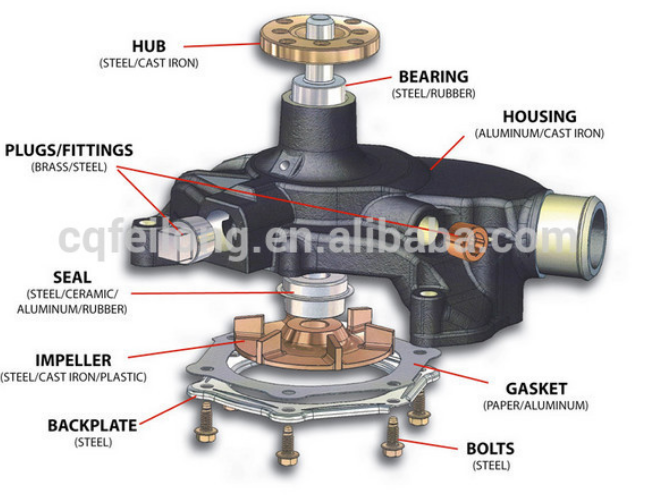

According to the engineer's statement of Feilong Jiangli .Automobile water pump is the key component of the engine cooling system. One end of the pump bearing inputs torque through the pulley, which drives the other end of the blade to rotate. In order to meet the development requirements of high power and high efficiency of the engine, higher performance requirements for pump bearings are put forward. Fracture, corrosion, peeling and grease leakage are common failure modes of automobile water pump bearings. Fracture is the most harmful. Therefore, it is necessary to analyze the failure modes of fracture and formulate corresponding preventive measures. The chemical composition, hardness, metallographic structure and heat treatment process of the broken shaft were determined by inspection and analysis to meet the requirements of relevant technical specifications. However, the toughness of the bearing after quenching is insufficient, resulting in low flexural torsional fatigue strength. The load of the pulley is transmitted to the pump bearing through the flange, and the receding groove at the back of the flange has a notch effect at the tip, which is the stress concentration position and the crack source is easy to appear. Therefore, it is necessary to change the heat treatment process of the pump bearing and optimize the geometry of the pump shaft.

-

Engine cooling water pump is the main part of the cooling system of automobile engine. Its function is to force the cooling fluid in the engine to circulate in the cooling system and reduce the influence of high temperature on the engine during the working process of the engine. Water seal is the core of the work of the pump. The movement of the water seal itself is very simple, just rotates with the shaft. . Water seal, pump body and bearing are super-hard matching mechanical seals. This kind of seals is composed of static rings and dynamic rings, which are perpendicular to the shaft, and the smooth and straight surface of each other, and do relative rotation. Coolant movement in the pump is very complex, different types of water seals, using different types of coolant, if the water package is equipped with problems, the engine coolant will appear seepage, then the pump bearing lubrication will be washed away, the entire pump function will be invalid. There are two main types of water seals: one is separated (rotating ring parts and static ring parts are respectively installed on the pump), the other is integrated (rotating ring parts and static ring parts are first installed together, and then installed on the pump), separated water seals are mainly used in larger pumps, now commonly used is integrated water seals.

-

- water seal

- engine cooling water pump

-

(and 1 more)

Tagged with:

-

When the pump is damaged, we should pay attention to the following items when replacing. (1) The real cause of the pump damage should be clear. Before replacing the pump, the radiator fan, thermostat and coolant should be determined. (2) It is likely that pumps with similar shapes but suitable for different types of engines will occur, so before installing the pumps, a comparison should be made between the new pump and the old pump removed, or a check should be made on the part number of the pump and the type of the engine to determine whether the selected pump is suitable for the model being repaired. (3) Water pump installation surface should be carefully cleaned and leveled. (4) When installing the pump, wet the seal ring with coolant first. If you need to use sealant, be careful not to apply too much. (5) Do not use the way of percussion pump shaft to install the pump. You should check the real reason for the difficulty of pump installation. If the excessive scale in the cylinder water channel leads to the difficulty of pump installation, steel wire brush or fine sand paper should be selected according to the scale situation. When installing bolts in water pumps, they should be tightened progressively in the direction of diagonal according to the prescribed torque, excessive tightening of bolts or causing damage to gaskets. (6) The tension of the pump belt must be strictly controlled according to the adjustment standard. Excessive tension of the belt, will cause bearing overload operation and early damage; and too small tension, easy to produce noise, serious pump can not work properly. Feilong Jiangli warm notes: If you can't replace it by yourself, please go to the warehouse.

-

It is unavoidable that the breakdown of the automobile water pump is in use. Common faults are as follows: (1) Bearing locking and fracture The causes of bearing failure may be the following aspects: bearing itself quality defects; bearing excessive impact load; product structure design defects; improper pump installation (such as knocking installation, belt tension, etc.) (2) Leakage of installation surface The possible reasons for leakage of installation surface are as follows: uneven application of sealant, resulting in leakage of seam; improper installation of sealing gasket; leakage of pump sealing gasket or improper installation operation. (3) Impeller damage Impeller damage is common in the form of impeller cracking, impeller loose from the pump shaft or impeller corrosion, impeller corrosion will not generally cause engine failure. When the impeller cracks or the impeller is loosened from the pump shaft, the coolant circulation speed becomes slower, which may easily cause the engine temperature to be too high. Damaged impeller may also impact the pump housing when rotating, causing cracking. If your car water pump is broken down , Feilong water pump can give you the prompt help.

-

One of the categories of automotive rubber products is belt products. Belt products are mainly used in automobiles to transfer torque power and speed, power from the power source engine to the need for power systems and places. It is installed in cooling fan, cooling water pump, brake compressor, booster pump, air conditioning system and steering system. The car belt is mainly V belt. Usually there are three kinds, that is, wrapped V belt, cutting V and multi wedge belt to cut W belt. Cutting V-belt has no coating on both sides, good flexibility, friction coefficient, with a large force, high linear speed, heat dissipation and fatigue resistance and energy-saving characteristics, commonly used rubber MIBR and R. Synchronous toothed joint is used for valve ignition of automotive engines. Its operating conditions are high speed, high power and high temperature. Thanks to Abby from Feilong Jiangli providing the basic data.

-

Due to the limitation of installation space and performance requirement, automobile engine cooling water pump has the characteristics of small volume, simple manufacture, and is conducive to mass production. The cooling water pump is usually made up of main parts such as pump body, impeller, shaft, bearing, water seal and pulley. According to the different structure of the engine cylinder block, the pump pressurized water chamber can be integrated on the engine cylinder block, and the impeller can also be separately configured as the core functional components of the pump, its diameter, outlet width, blade structure shape and other parameters and structure design directly determine the performance of the cooling water pump. There are many kinds of cooling water pump structure, according to the impeller material is different, can be divided into cast iron impeller, stamping impeller and plastic impeller; according to the impeller has no cover plate can be divided into open impeller and closed impeller; according to the impeller blade shape is different, can be divided into straight blade impeller, single curvature blade impeller and space twisted blade impeller. Feilong Jiangli has all the kinds of impellers. With the development of science and technology, cast iron impellers are still used in the cooling water pumps of trucks, buses and other heavy-duty vehicles and a few self-owned passenger cars. Pressed impellers are mostly used in Japanese passenger cars, plastic impellers are mostly used in European and American advanced countries, and three kinds of impellers are used in domestic self-owned brand cars, but with With the introduction of new technology from abroad, plastic impellers have been used in newly developed machines. When cooling water pumps work, the coolant rotates with the impeller on the one hand, and flows out of the rotating impeller on the other.

-

Automobile rubber products are indispensable components in automobile parts. According to the different types of cars, each car needs to install about 100-200 kinds of rubber products, to use more than 200-500 rubber accessories. In addition to tires, different sizes of cars vary, and the consumption of rubber materials is about 15-60 kilograms. A car's rubber products (excluding tyres) account for about 6% of the total vehicle cost. There are more than 1000 kinds of non tire rubber products in automobile industry, and there are about 8000 specifications. According to statistics, the automotive industry accounts for more than 70% of the global annual consumption of raw rubber, including 60% of tires, 40% of automotive rubber accessories. High speed, safety, comfort, energy saving and environmental protection are the goals pursued by modern cars. With the development of modern automotive technology, the requirements for automotive rubber products are becoming increasingly stringent and demanding. It is not only required that rubber materials with various special properties meet the new technical requirements of automobiles, but also that rubber materials have higher physical and mechanical properties, such as aging resistance, high temperature resistance, low temperature resistance, new fuel and excellent performance. The dynamic fatigue performance, durable service life and so on. In fact, every high performance of modern automobiles depends on the technical progress of rubber products to provide protection. The performance and quality of automotive rubber products play a crucial role in improving the quality of automobiles. It should be noted here that although rubber products always play a role in a variety of mechanical equipment accessories, but rubber accessories are always about the technical progress and level of the host. Therefore, it can be said that the technical progress and quality level of automobile rubber products can basically reflect the technical level of automobile. If you want to learn more about the rubber products,please visit www.fljlcq.com.

-

- rubber products

- automobile rubber products

- (and 1 more)

-

This power assembly mounting arrangement design uses more mature left, right engine side and transmission side three-point mounting arrangement, are rubber mounting. In the road test of NVH performance of mounting system, one measuring point (three-way sensor) is arranged on the active side (i.e. connecting engine side mounting bracket) and the passive side (i.e. connecting body side mounting bracket) of each mounting. The noise measuring points are located in the driver's right ear, the right ear of the non-left seat and the right ear of the rear left seat respectively. Set up a measuring point. Under the condition of slow acceleration, the active and passive side brackets of the engine have obvious resonance bands around 260 Hz, and the maximum speed of the engine is about 3860 rpm. Under the condition of slow acceleration, the sound pressure inside the vehicle has obvious peak value at about 3860rpm of the engine speed. (Thanks to the engineers from Feilong Jiangli providing information)

-

Test steps (1) oil release: unscrew the oil bolts and put the oil in the right container. If all the oil in the oil pan can not be dried through the oil drain bolt hole, the remaining lubricating oil in the oil pan must be drained through the oil pumping equipment. (2) install the oil drain plug, tightening torque is generally 25±3N • m (3) refueling: oil can be added from the oil filler cap or scale pipe orifice. But if you add oil from the top of the oil filler, it takes more than 10 minutes to keep the oil flowing to the oil pan. If you add oil from the caliper nozzle, the time can be shortened to 3 minutes. (4) taking the design capacity of 4 to 5 liters as an example, for the first time, the lower limit capacity of the engine oil is 4 liters. (5) wipe the ruler clean and slowly insert it into the ruler tube. After inserting into position, stand still for a few seconds, then pull out the scale, observe and record the position relationship between the level and the scale. During observation, the head of the ruler should be washed down or flat. (6) add 0.5 liters of oil according to step 3 and repeat step 5. There is no midline requirement on the ruler. This step is for reference only. (7) repeat step 5 according to step 3 on the basis of step 4 and add 1L oil. The relationship between the level and the level of the liquid was observed and recorded. according to the results of steps 5, 6 and 7, check whether the calibration scale and the minimum scale scale are correct

-

When calculating the scale of the oil scale, it is best to choose the flange face of the ruler tube. The reason why the flange is chosen as the measuring reference is that the ruler's position in the engine is completely determined by it. (1) B is the length of the axis of the ruler. After the scale tube is arranged on the engine, it can be directly measured from the digital module. (2) C is the length of the ruler tube inserted into the flange installation surface. The length is set according to the length of the ruler. If the condition is allowed, it is best to keep the ruler to protect the head of the ruler, so that the measuring head of the ruler is parallel to the wall of the ruler, and the scraping of the scale section of the ruler is reduced. (3) D is the value from the flange surface to the maximum scale, corresponding to L1 in Figure 6. Similarly, the value from the flange surface to the minimum scale is L2. It is easy to get the theoretical distance of the ruler: the distance between the handle of the ruler and the mouth of the ruler to the maximum level of the level of the level of the level of the oil level: AMAX=B-C+L1, the same, the distance between the yardstick and the ruler's pipe mouth to the minimum level of the level of the level of the oil level: AMIN=B-C+L2.

-

- oil dipsticks

- auto parts

-

(and 1 more)

Tagged with:

-

(1) Complete the modeling of the oil storage space in the lubrication system according to the relevant parts of the lubrication system. (2) Through the automatic measurement function of ProE software, the oil storage volume of oil pan is cut to find the defined volume at the normal loading angle. It is assumed that the maximum oil injection amount of an engine is 5L (3) Assuming that the ruler's direction in the ruler tube is consistent with the direction of the ruler tube, the mark value of the maximum scale of the oil scale is to select (2) the intersection point of the middle line of the liquid level and the ruler tube. Note the distance from the flange flange to the maximum liquid level from the scale tube L4. (4) similarly, according to steps (2) and (3), the measured minimum oil capacity is defined L2 L1 and L2 are the values of maximum liquid level and minimum liquid level calculated by scale theory.

-

The measuring rod part of the oil gauge generally has three structures: steel wire, steel belt (Bian Chi), and many winding wires. Among them, spring steel wire is commonly used in steel wire structure, and the material is hard, which is suitable for the relatively slow bending ruler tube. The multi strand wire is easy to insert and plugged in the bending scale tube, but the price is higher. The material of flat ruler generally chooses 0.8mm~1.2mm stainless steel strip, and the price is relatively low. As the core part of the ruler, the head of a ruler is the most important part of the ruler. In the drawing, it is easy to rub with the ruler tube that matches with it. The particles produced by the friction will fall into the lubricating oil. The unclean lubricating oil will cause great wear to the bearings of the engine. In the indicator part of the scale, the head can be designed as a roller structure, which is not only effective. The scale has reduced the tube pulling force of the ruler and reduced the scraping of the ruler head and the ruler tube. For the oil gauge with steel strip structure, in order to make the gauge clearly indicate the position of the liquid level, it is easier for users to read the oil gauge. Generally, the head of the flat ruler is treated with sand blasting or press mesh, and some rhombic pits can be set on the head of the plastic. These pits are disconnected from each other, so that the oil can climb up the trough under the siphon effect, which affects the accurate reading of the scale.

-

The oil dipstick is a common part in the engine lubrication system. Its core function is to ensure that the oil of the engine oil bottom is in a reasonable range, and also has the function of sealing the crankcase and providing support for other accessories. Although the structure is simple, it is essential on the engine. Oil gauge is widely used by automobile manufacturers at home and abroad because of its cost advantage over oil level sensor. The oil dipstick is usually used in combination with the ruler tube, so that the user can easily understand the oil level in the engine and ensure the engine oil storage in a reasonable range. Reliable lubrication of engine is guaranteed by lubricating oil rice. Too much oil or too little will affect the normal operation of the engine. The addition of the lubricating oil must be appropriate. When the oil in the engine oil bottom is insufficient, the engine is not lubricated and the engine is badly lubricated. The engine will seriously damage the engine. If the engine oil is too much oil, the engine will stir the engine oil sharply in the end of the crankshaft and connecting rod, not only increases the engine power in the engine, but also increases the power inside the engine. Loss, but also will increase the amount of oil splashed onto the cylinder wall, resulting in the phenomenon of burning oil. Therefore, the engine oil sump must be controlled within the proper range.

-

The motor torque is through the silicon (stator) on the coil after the electricity generated magnetic field LED permanent magnet (rotor) operation. A magnetic system with a complete coupling of n (n-even)-filled magnets to make the parts of a magnet mutually integral. When the magnetic pole of the stator coil is opposite to the magnet's magnetic pole, that is, the displacement angle between the two poles is φ=0, the magnetic energy is the lowest, and the magnetic energy is the largest when the magnetic pole rotates to the same pole, i.e. the displacement angle between the two poles is φ=2π/n. After removing the external force, the magnetic force will restore the magnet to the lowest energy state due to the repulsion of the magnet. So the magnet produces movement, driving the magnetic rotor rotation, brushless pump impeller driving force is brushless motor. Brushless water pump through electronic commutation, no need to use carbon brushes, magnet rotor and stator silicon have multistage magnetic field, when the magnet rotor relative to the stator rotation angle will automatically change the direction of the pole, so that the rotor always maintain the same pole rejection, so that brushless DC magnetic isolation pump has a higher speed and efficiency. Feilong electric water pump, high quality, good price. Welcome to get more information.

-

According to the different driving mode, the pump is generally divided into mechanical pumps and electric pumps. Most of the engines now use mechanical pumps, and electric pumps have been used in some newly developed, technologically high engines, such as the BMW 6-series (E63) engine. (1)Mechanical pumps The mechanical water pump is driven by the engine crankshaft through the driving tape, and its rotational speed is proportional to the engine speed. The working methods of mechanical pumps have both advantages and disadvantages. When the engine is working under high speed and heavy load conditions, the heat produced by the engine, the high speed of the pump makes the circulating flow of the coolant increase, so that the cooling capacity of the engine can be improved. When the engine is working under low speed and heavy load, such as traction other vehicles or open air conditioner, the engine speed is low and the speed of pump is low. , which lowers the engine's cooling capacity. (2)Electric pumps Electric water pump has brushless electric pump and brush electric pump. The electric pump is controlled by the engine control unit through the current, which is not affected by the engine speed, and can be flexibly operated according to the actual cooling of the engine. Because the electric pump consumes very little engine power, the fuel consumption of the engine can be reduced after the electric pump is used. Thanks for your reading. If you have any questions, please contact me [email protected]. https://s1.ax1x.com/2018/07/21/P8R9aQ.jpg

-

The main performance parameters of the centrifugal pump as follows: 1. Flow Flow is also called displacement, the amount of water raised. It is the amount of liquid discharged by the pump in the unit time, has two representation , one is volume units and the other is weight units. Q expression for volume flow, the unit is m³/s, m³/h, and L/s. G expression for weight flow, the unit is T/h, Kg/s. The relationship between the weight flow and volume flow is G=γ Q (γ=liquid weight, kg/m³) 2. Head Unit weight liquid through the pump after the energy is commonly known as the lift, also known as the total head or full lift. Expressed in H, the unit is m For high-pressure pumps, sometimes also approximately with the pump outlet and the inlet pressure difference (P2-P1 ) to indicate the head size, at this time the lift of the expression is H=104(P2-P1)/γ P2 —outlet pressure of pump (kg/cm2) P1 —inlet pressure of the pump(kg/cm2) 3. Speed The rotational speed of the centrifugal pump refers to the number of revolutions per minute of the shaft, expressed in n, the unit is r/min. 4. Power The power of the centrifugal pump refers to the axial power of the centrifugal pump, that is, the original motive to the pump power, expressed in N, the unit is kw. The product of the pump's weight flow and head is called the effective power of the pump. Expressed in Ne, the unit is kg*m/s. The expression is Ne=GH=γQH The difference between shaft power N and effective power Ne of centrifugal pump is the loss of power in the pump, its size can be measured by efficiency. The efficiency of the centrifugal pump is the ratio between the effective power Ne and the shaft power N, expressed in η, η=Ne/N 5. Specific speed

-

Centrifugal pumps are widely used in automobile engines. The basic structure consists of a pump house, a connecting plate or a belt pulley, a water pump shaft and a bearing or shaft bearing, a pump impeller and a water seal, etc., The water pump is the main component of the automobile. The engine drives the pump bearing and the impeller rotation through the belt pulley, while the pump coolant is driven together by the impeller rotation. Under the action of centrifugal force, the coolant is flung to the edge of the water pump house, which creates a certain pressure and then flows out of the channel or water pipe. When the coolant is thrown out, the pressure at the center of the impeller is reduced. The coolant in the water tank is sucked into the impeller by the water pipe under the difference pressure between the pump inlet and the impeller center to realize the reciprocating cycle of the cooling liquid. The grease which should be prevented from the leakage of coolant is used for lubricating on the shaft bearings. The grease leakage should be prevented at the same time. The seals and gaskets are used for preventing leakage of water pump. If you need the water pump, please contact me [email protected]. It’s my pleasure to offer service for you.

-

Need the book about auto water pumps

Mengjuan Zhu replied to Mengjuan Zhu's topic in Help With Car or Truck Repair

Thank you very much. -

Who know where can buy the book in attachment? Contact me via [email protected]